Light Water Reactor Fuel Performance

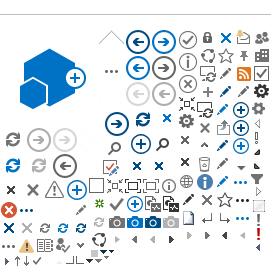

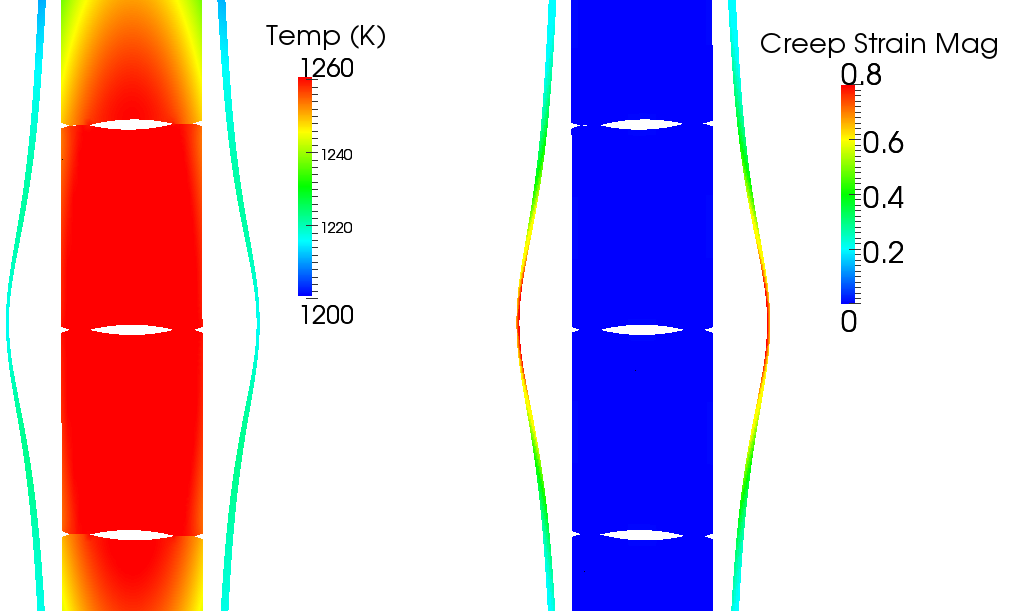

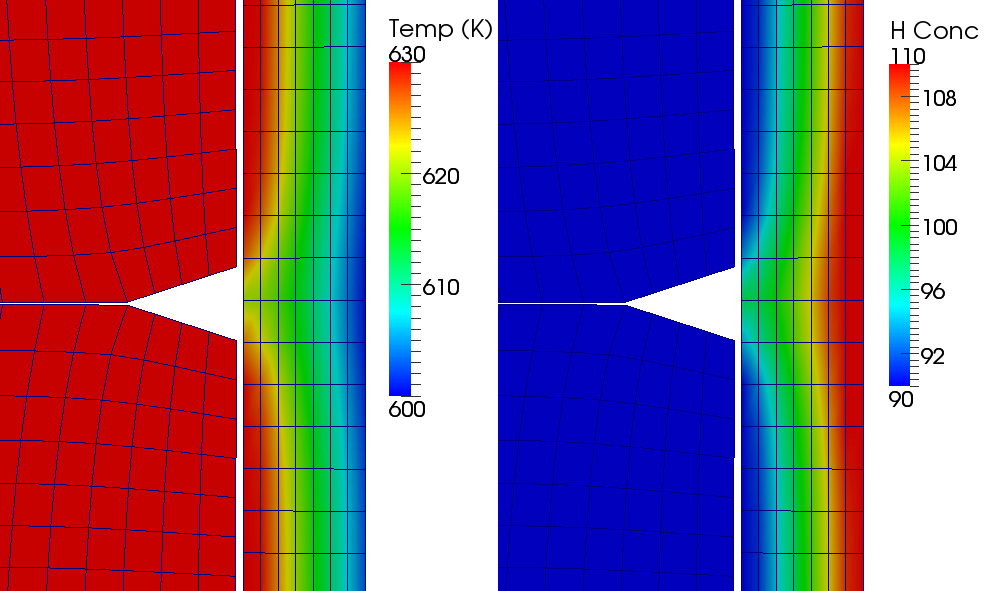

Bison simulates the thermo-mechanical response of light water reactor fuel rods in 1 , 2 , or 3 dimensions. Bison includes models for UO2 fuel behavior (e.g., thermal conductivity degradation), Zircaloy cladding behavior (e.g., cladding creep), and gap behavior (e.g., reduced conductance due to fission gas release). The images show temperature and stress for a rodlet with a defective fuel pellet, cladding ballooning, and the concentration of hydrogen at the relatively cool boundary between fuel pellets.

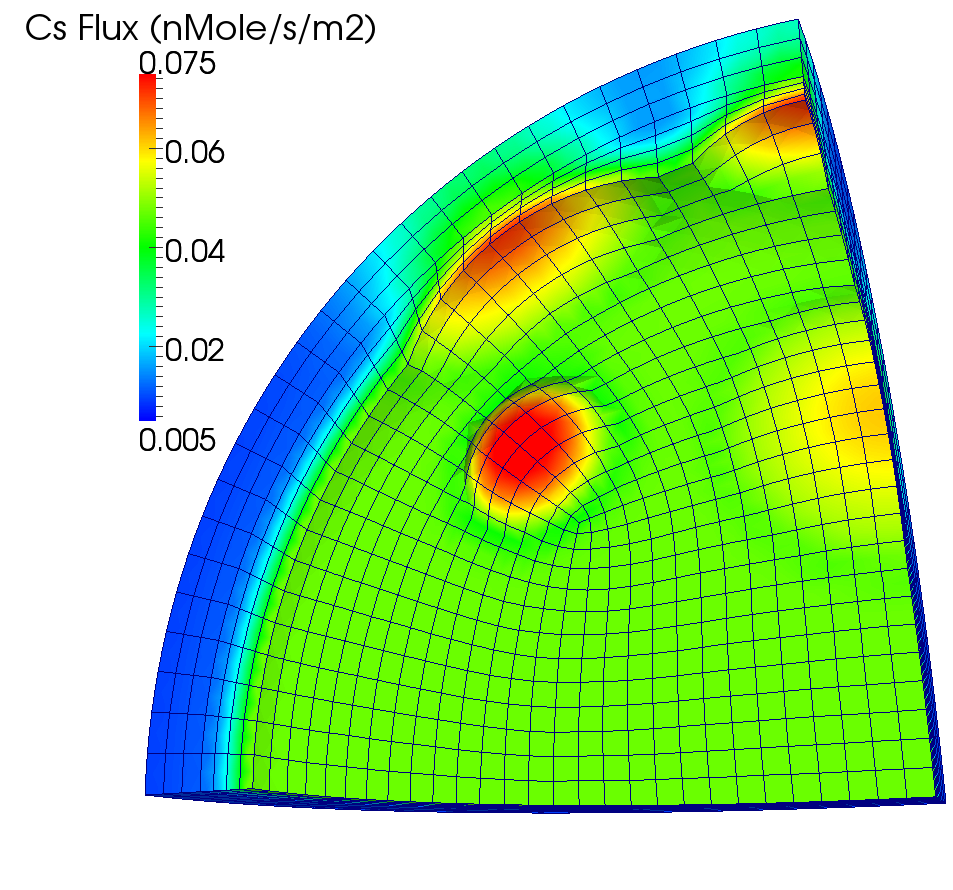

TRISO Fuel Performance

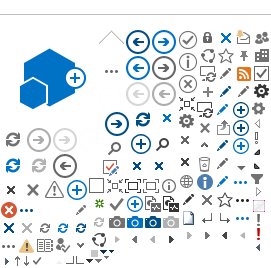

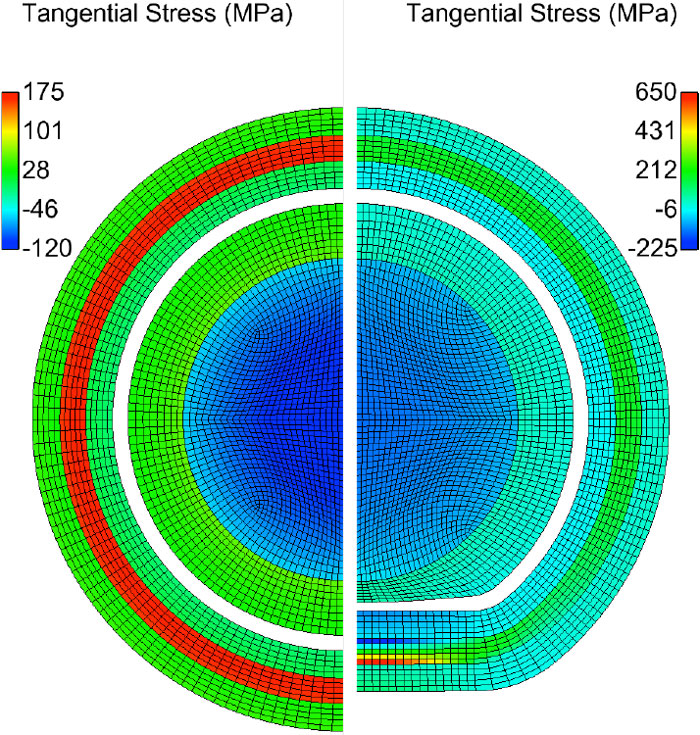

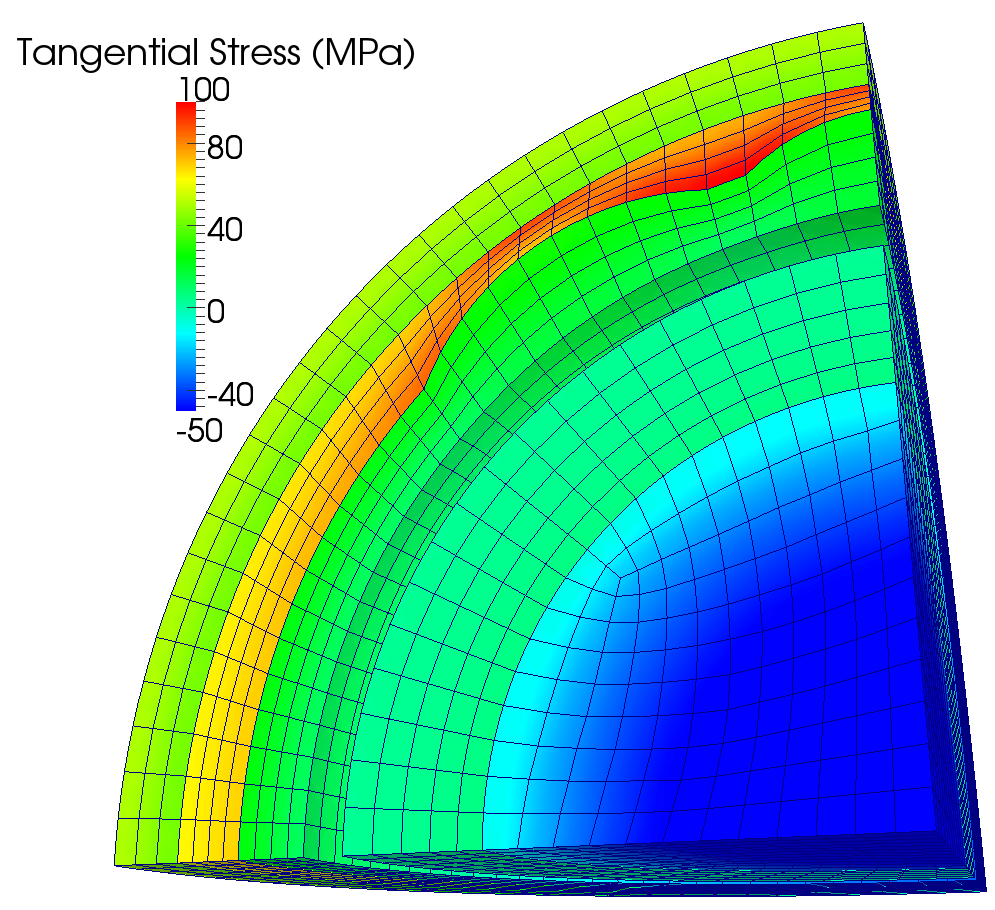

Bison also simulates TRISO fuel performance in 1, 2, or 3 dimensions. Spherically symmetric cases run quickly with 1-dimensional meshes, while more detailed information can be gained regarding defective fuel through the use of 2- or 3-dimensional meshes. The images show tangential stress for a fuel particle with a flattened surface, tangential stress in a particle with a thinned SiC layer, and Cs flux in a particle with a thinned SiC layer.

Other Applications

Bison is applicable to a variety of fuel types and has been used to analyze metal fuel, plate fuel, and novel fuel configurations.